How About Those Notches?

October 15, 2015

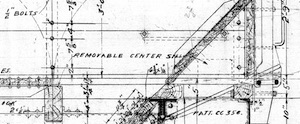

Some small print on the plans explains it: "5" x 9" removable center sill Dwg. No C-1852". The doors covering the hopper were wood, reinforced with metal strips, and weren't strong enough to support a full load on their own. A thirty foot 5" x 9" beam (or maybe two beams, one stretching to each end of the car) sat underneath, on top of the cross-beams, acted as support for the doors. One of the end drawings also helpfully notes that the sill would be stored behind the doors when the hopper doors were opened.

Engineering drawing excerpt from Southern Pacific Common Standard plan C-1652 "Work Car Class W-50-3", in the collection of the California State Railroad Museum in Sacramento. If you're obsessed about these cars as much as I am, call them up and ask about getting a copy of the full plan for yourself.